Pretreatment/potable water generation

The activated filter media (AFM) of the potable water generation, drinking water generation and industrial process water generation in different industrious.

• Crystal clear water

• No bacterial contamination of filter material => less inorganic chloramine

• No chlorine odor due to almost no presence of Trichloramine

• Healthy air due to minimized production of volatile chlorine disinfection by-products

• Low need for disinfectants.

Soft water generation (Softener)

Soft water generation (Softener)

Softening filters are mainly used to remove hardness components from water, such as calcium ions (Ca² ⁺) and magnesium ions (Mg ²⁺), to prevent the formation of scale. The working principle of filters mainly relies on a process called ion exchange. Inside the softening filter, ion exchange resin is usually filled. This resin has a negative charge on its surface and can attract positive ions (such as calcium and magnesium) in water. When water containing hardness components flows through these resins, the sodium ions (Na⁺) on the resin exchange with the calcium and magnesium ions in the water, thereby adsorbing the calcium and magnesium ions in the water onto the resin, while the sodium ions are released into the water, replacing the original calcium and magnesium ions. Because sodium does not cause scale problems, the treated water becomes soft water. After a period of time, as more and more calcium and magnesium ions are adsorbed, the resin will gradually become saturated, and it is necessary to regenerate the resin. The regeneration process involves adding high concentration saline solution (sodium chloride solution) to the resin, allowing sodium ions to replace calcium and magnesium ions on the resin again, restoring the resin's exchange capacity for continued use.

Softening filter automatic forward and reverse washing (fully automatic multi way valve control).

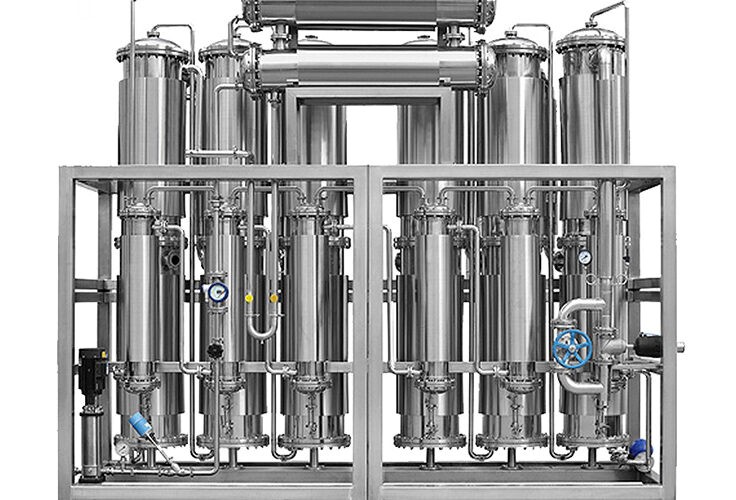

Pure water generation

Pure water generation

Pure water can be generated through various methods, with distillation and reverse osmosis being the most common. Distillation involves boiling water and condensing the vapor to collect pure water, while reverse osmosis uses pressure to force water through a membrane, separating impurities. Other methods include filtration, UV purification, and chemical treatments like chlorination or the use of purification tablets.

Pure water Distribution

Pure water Distribution

Pure water distribution refers to the process of delivering purified water to various points of use, ensuring its quality, quantity, and pressure are maintained. This involves a system of pipes, pumps, reservoirs, and instruments to monitor and control the distribution process.

Water for Injection (WFI)

Water for Injection (WFI)

Water for Injection (WFI) is a highly purified and sterile water used in the pharmaceutical and biotechnology industries. It's specifically used for preparing injectable medications, ophthalmic products, and other sterile formulations, as well as for cleaning and rinsing equipment in these industries. Due to its critical role, WFI must meet stringent quality standards, including being free from pyrogens (fever-causing substances) and microbial contamination.

Reverse Osmosis (RO)

Reverse Osmosis (RO)

A Reverse Osmosis (RO) plant is a water treatment facility that uses pressure to force water through a semipermeable membrane, removing contaminants and producing highly purified water. This process is commonly used for desalination, wastewater treatment, and to produce potable water. RO plants are versatile and can be used with various water sources, including tap water, groundwater, and saltwater.

Click to see More

Drydenaqua website

Calplas website

Click to see More

Drydenaqua website

Calplas website